The fabless business model is nowadays a trend in the industry. Developing an own process technology is not an option for most companies, and it is not profitable in the short- or mid-term. Moreover, the required investment is not feasible for a majority.

In the last times, the semiconductor crisis bring the IC industry to the newspapers and the word “fabless” is being heard more and more in the general press. But… what is exactly a fabless company?

The word “fab” reffers to a foundry, the factory where the integrated circuits or chips are manufactured.

A fabless company is an IC company which only designs the chips and outsources the manufacturing process. They use the IC node technologies provided by the foundry and each design is bound to a specific technology, for example, TSMC 28nm general purpose, XFab 130nm or Gf 55nm.

There are at least 2 or 3 levels of fabless companies:

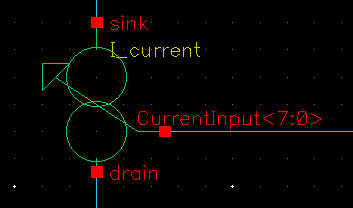

It starts with the IP vendors: They design and silicon prove reusable circuit blocks or parts with a concrete functionality that can be reused in different chip designs. For example current sources, band gaps, oscillators, comparators, voltage references, ADCs, etc. These companies sell the licence to use their block to multiple chip makers. They don’t sell any physical product, but a layout format (usually GDSII) file. ARM is the most famous “IP vendor fabless company” which sells its microcontrollers to multiple manufacturers.

Then regular fabless companies design a chip, manufacture outside in an external foundry and then sell the physical chip with their brand or company name. Qualcomm, Nvidia or AMD are fabless companies.

Fabless but with its own technology. If you want to develop a particular functionality which is not feasible to build with commercial processes or you want to beat your competitor. They work together with a foundry to develop their own process flavour modifying an existing one. For example high voltage, photosensitive or optical devices.

The Vertical and Horizontal Business

In general, 2 business strategies or models can be found in the industry: Vertical and Horizontal.

- In the Vertical approach, the full IC design, process development and chip fabrication are completed in the same company. For example Samsung, Intel, etc.

- Horizontal: They specialise only in chip design step, outsourcing the chip manufacturing and technology process development.

What is better?

It depends,

The vertical integration boosts the internal profit, has direct and immediate contact with the final consumers and responds faster to changes in the market, reducing the time-to-market. Also, they have direct control of the foundry fabrication times and slots, which are critical if a semiconductor shortage occurs.

The amount of money necessary to create, develop a process technology and run a foundry is enormous and not affordable for the majority.

The horizontal (fabless) business model makes it “easy” for a startup, company or even a university to fabricate their own chip with “few” resources.

Fabless companies don’t have direct access or control to the foundry specs and parameters, nor to the fabrication schedules or slots. Therefore, the total fabrication time is longer increasing significantly the iteration time of the IC design flow.

Fabless companies may suffer from the untrust issues in the semiconductors industry. As I talked about before in this other article, IP and IC Piracy are there and increasing. The number of detected counterfeit chips cases which are coming out is increasing.

But why does the IC industry is moving to horizontal strategies??

All about Costs

The cost of installing, running and upgrading a foundry is incredibly huge, needing an enormous initial investment. For example, the cost of having a 90 nm foundry is more than $2.4 billion, 28nm cost $6 billion and 5nm cost around $16 billion, and the price has been increasing over time with new and smaller technology nodes [1].

Also, a change to a new technology node every two years (like Moore’s law predicted) is not mandatory for a fab, but to be considered. Even it makes more expensive with the technology nodes approaching ∼10 nm. Therefore, it is almost impossible for most of the vertical semiconductor players to afford such a high cost. Although the cost is the critical controlling parameter that determines the price of final products.

To compete in the global market, IC designers are outsourcing their designed ICs to offshore foundries for fabricating their chips.

So interesting!

Everything is very open with a very clear explanation of the

new world of microelectronics!!

Thanks for sharing!